City Center: Driving Revenue in Saratoga County

WRITTEN BY DAN LUNDQUIST | PHOTOS PROVIDED UNLESS NOTED

Today it is close to impossible for most people to imagine that Saratoga Springs has ever been anything other than a crown jewel. Not just in Upstate NY but regionally and even nationally.

Almost two hundred years of Health, History and Horses – romanticized and true – cap the mystique of the “city in the country,” but managing that glowing brand has required enormous effort on the part of a great many people over years. It has required vision and risk, investment and experimentation. And all of that has rested on a foundation of belief in, and dedication to the city of Saratoga Springs.

One of the most visible and important examples of that is the Saratoga Springs City Center which, along with its companion hotel, sits at the north end of Broadway.

TOUGH TIMES

Few today can imagine the distress that longtime Saratogians – many returning veterans of WW2 – felt when they assessed the state of the city in the mid-twentieth century. The few grand hotels that helped put Saratoga on the map in the nineteenth century were in shambles as was most of the city. “There had been no racing for three years due to the war, businesses had failed, and it seemed to my father and his generation that Saratoga was dying,” said Charles Wait – who succeeded his father as chairman of the Adirondack Trust bank and himself became a leader in the rebirth efforts. “Things had become so dire that NYRA was seriously considering closing its Saratoga operations in favor of Downstate tracks. It took the resolve of old racing families to keep our historic track open,” said Wait.

Plagued by deteriorating infrastructure, an eroding business base, crime and illicit gambling Saratoga Springs had become a town that many wanted to avoid, so much so that even some prominent families relocated north and east of the downtown area.

In 1965 the 72-year-old Convention Hall – on the south of Congress Park with a seating capacity of 5000 – burned to the ground. What could have been a nail in the coffin became a call to action.

Overlooking the Saratoga Springs City Center and pedestrian connector from the parking structure, 2020. Photo by Thomas Dimopoulos.

CALL TO ACTION

It took decades of resolve, planning, and arduous execution – in stages – to get the city on the trajectory that has earned pages of accolades ranging from Best Small City in NY to Best Main Street in the USA to inclusion in “Five hideaways that aren’t the Hamptons.” The list goes on from the serious to the comical: Healthiest Community in NYS and “most bars per person.”

A veritable Who’s Who of prominent local families – generations of local families – rose to address what they saw as a “swim or sink” challenge that would span urban renewal, historic preservation, revitalization of downtown, and benefits to the larger region. This would require great funding, state and federal support, and the buy-in of the citizenry. Wait colorfully recalls the many attempts to coalesce public support and secure funding from the proverbial cloakroom arm twisting to the participation of thousands in civic pride projects. “In many different ways, many different people supported the kind of groundswell that was necessary to achieve Saratoga Springs‘ rebirth,” he said. “What seemed to be a very risky venture has turned out to be the foundation for the prosperity we enjoy today.”

BEYOND THE SUMMER PLACE TO BE

Though a number of other important constituent supporting steps had been taken in the 1950s, many cite the community-based creation of Saratoga Springs Community Hotel, Inc. in 1961 as a high profile turning point. This effort created the Holiday Inn on South Broadway and was the beginning of – and a pioneering reason for – Saratoga’s return, albeit in an updated and sustainable way, to destination status.

Promising vital signs - community involvement, support of outside agencies, the creation of SPAC and the relocation of Skidmore to North Broadway – gave civic boosters reason for optimism but the situation was by no means secure. A Plan of Action was created with the goal of making Saratoga Springs the Year Round Place to Be. Essential to the success of that ambitious goal would be creating a reason for people to come to Saratoga all year long.

ENTER THE CITY CENTER

In July 1983 the SSCC Authority – a so-called public benefit corporation – was formed to oversee pre- and post-construction management of the center. As an “authority” it would have more freedom to operate. Utilizing insurance money from the old Convention Hall fire – $800,000 which had been accruing interest over two decades – and creating a new resource channel through a one percent increase in local sales tax, the planning and construction for this new facility began. When completed the City Center would add 37,000 square feet of space and seat as many as 2,500 people, thus filling what had been a 20-year handicap for the Spa City.

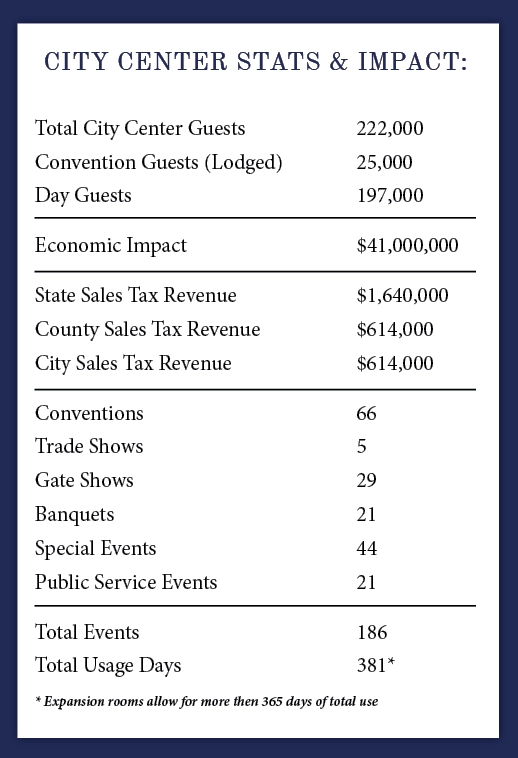

According to City Center director Ryan McMahon, the venue typically hosts over 160 events close to 300 days a year with NYS associations, trade shows, union meetings, and corporate business forming the “bread and butter” of Center activity. But it’s a community resource as well as varied cultural showcase.

After 28 successful years it had become increasingly clear that, in order to sustain that trajectory, an expansion of the City Center was necessary.

When asked why he helped secure $12M in state funding to support expanding the City Center, the late Senator Joe Bruno, a champion of the region, replied “Why the City Center? Because Saratoga Springs competes with the whole world as a destination. When you expand a facility like this you open your market up.”

In 2011 the expansion and “refresh” was completed, adding 12,000 square feet of space (58,000 square feet of space when the City Center is combined with the connected Saratoga Hilton). Along with the 2019 completion of a multi-level attached parking facility with over 600 spaces, both Discover Saratoga and City Center staff found that several groups that had outgrown the old facility were able to return. In addition, new groups had been attracted.

Since the early ‘80s City Center guests have created potential sales of $470M, which has generated more than $33M in sales tax revenue. The City Center has generated $321M in sales that are subject to city, county and state sales tax. “It’s not only an enviable economic engine,” says Center director Ryan McMahon, “but the very high satisfaction levels visitors report get shared when they return home, creating priceless word of mouth endorsements.”

Regarding the importance of the City Center, Saratoga County Chamber of Commerce President Todd Shimkus quoted a chamber publication, Saratoga Springs – Transformation by the Passion of a Community. “This publication tells the story of the city’s revitalization and includes the creation of the City Center,” he said. “The story begins: ‘Many consider the opening of the City Center in the summer of 1984 to be one of the most important achievements in the rebirth of Saratoga Springs. Without it, Saratoga would not have the substantial convention business that has strengthened the city’s economy.’”

Discover Saratoga’s president Darryl Leggieri agrees: “The City Center is such an important part of our local economy and has made all the difference in supporting Saratoga as a year-round destination; it brings thousands of visitors to town each year who stay in our hotels, eat in our restaurants, and shop in our boutiques. Having the Center surrounded by a safe, walkable, and vibrant downtown gives us a tremendous advantage when selling Saratoga. This strengthens the local economy for all, which continues to strengthen the Saratoga Brand. It’s a win-win.”

The years of Covid hit the Center’s bottom line hard. “In 2019 the SSCC’s earned revenue was just over $1.1 million. There has clearly been a drop with COVID so 2021 was only $430,000.

In 2022 we are getting back on track. Even after a first quarter with almost no events revenue will be over $900,000” McMahon explained. But McMahon and his team were not idle when the Center was offline: “we were able to take advantage of our status as a state authority to complete the much-needed parking facility when most other projects were halted and it gave us an opportunity to increase our collaboration with Discover Saratoga, the Chamber, the Downtown Business Association, and others.” This all contributed to the speedy rebound that McMahon’s numbers reflect. “We showed a macro economic impact on the area of $40M in 2019. That dropped to $15M last year but we are well on the way to reaching new highs,” he said.

“Some very forward thinking people worked hard to create the SSCC in the 80’s which was one of the keys to Saratoga Springs current success. It is a symbiotic relationship where the SSCC helps to support the downtown business community and the presence of a vibrant downtown makes the SSCC a more desirable venue. This allows us to punch out of our weight class,” McMahon says with pride.

SERENDIPITOUS BRAND MANAGEMENT

Echoing the interdependency of the local marquee elements – SPAC, downtown, the City Center, and Skidmore College – the view expressed by all is that Saratoga Springs sells itself.

The “city in the country” has a diverse portfolio of offerings, attracting diverse audiences generating hundreds of millions of dollars to both the city and region. So, if you have a moment of frustration trying to navigate Broadway, whether it’s summer’s race season or winter’s Chowderfest, we’ve become The Year-Round Place to Be!